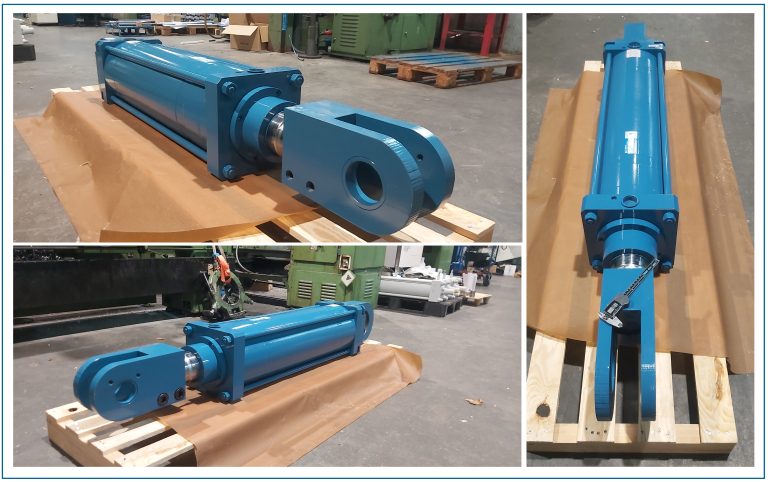

It may seem to you that it is just another cylinder, like any other. But it is not.

It is an all-steel pneumatic cylinder, 280mm bore and 797mm stroke, with a female fork at the front and a male ball joint at the rear. Designed for extreme conditions.

It incorporates an oversized 125mm pistón rod, considerably larger than usual, which improves the load capacity and prevents vending. Both charactheristics, essential to generate the force required in this application.

Many of the components used in the manufacture of this cylinder are treated to improve the strength of the assembly, reduce wear and provide protection against corrosion, which is basic in harsh environments.

In addition, seals are protected, thus extending the service life of the cylinder. Seals are critical components that wear out over time. This feature contributes to increased cylinder durability and reduced maintenance.

At 6 bar pressure it generates a force of 3.69 tonnes, making it a very suitable solution for demanding industrial applications, when installing a hydraulic cylinder is not an option.

As a nutshell, this steel pneumatic cylinder with oversized piston rod and treated components is an ideal solution for applications in extreme conditions where significant force and long-term durability are required. Corrosion protection and extended seal life are additional features that make this cylinder suitable for harsh environments.

They say beauty is on the inside, but, without being overbearing, I find it beautiful even on the outside ?.

Great job, team!

told that we fitted in perfectly with the Partners group. Partners are companies that have the capacity to cooperate with the sector either because of the products they manufacture or the services they offer.

told that we fitted in perfectly with the Partners group. Partners are companies that have the capacity to cooperate with the sector either because of the products they manufacture or the services they offer.